World-Leading Printing Precision

STRONGER

The WJ530 features Flashforge’s patented high-precision MJP technology, delivering ultra-high resolution at 2900 × 2900 × 1700 DPI with layer thickness as fine as 15 microns. This exceptional accuracy produces smoother surface finishes and reduces post-processing time by 25% to 33%, helping jewelry manufacturers cut labor costs, accelerate turnaround, and gain a competitive advantage in high-volume jewelry manufacturing.

ULTRA-HIGH PERFORMANCE WAX 3D PRINTER

The WJ 530 is a batch production WaxJet printer designed for jewelry manufacturing plants or printing service providers with wax mold production needs.

Stable & Durable

Patented self-developed wax circulation control system, 365*24-hour high-intensity testing, more durable printhead.

High Wax Material Utilization Rate

Stable output with a wax material utilization rate of 58%-60%, advanced technology and reliable printing improve utilization, reduce waste, and maximize production efficiency.

Intelligent Monitoring

Wi-Fi connectivity & 2K HD camera, monitor printing in real time for worry-free production

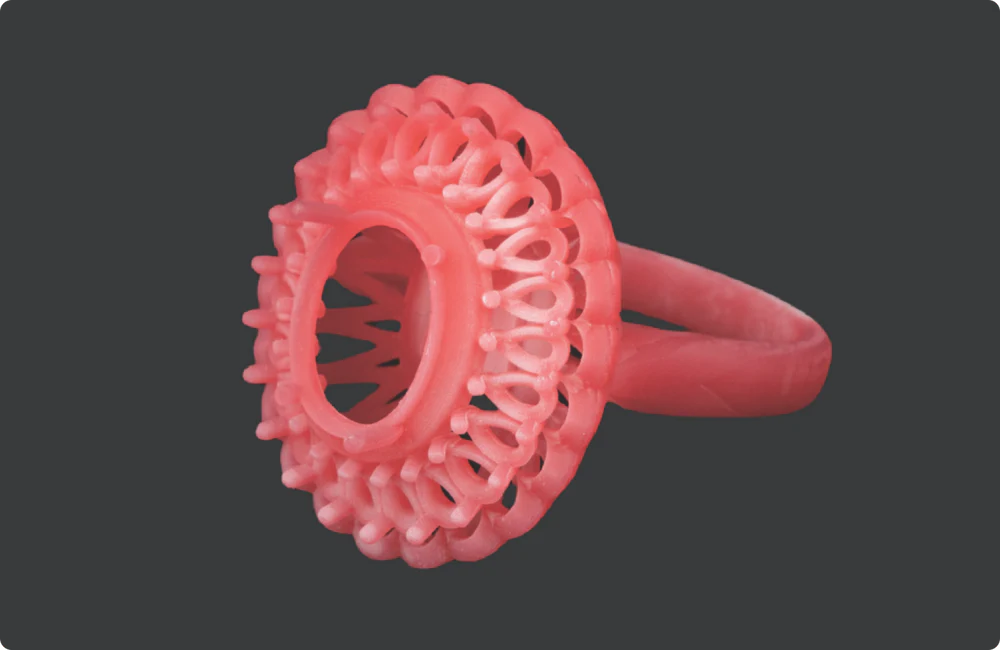

Exceptionally Easy to Electroplate

The red wax mold made from red wax perfectly adheres to electroplated silver coating.

Product upgrade comparison

Product upgrade comparison

Technical Parameter

| Printing Technology | MultiJet Printing (MJP) | Material Name | FFWJ1200 | FFWS3200 |

| Build Volume | 289*208*150mm | Material Type | Part Wax | Support Wax |

| Printhead | 3 piezoelectric printheads | Net Weight | 3.0kg/bottle | 3.6kg/bottle |

| Dimensional Accuracy | 20mm ±0.04mm | Composition | 100% wax | Wax support material |

| Resolution | 2900*2900*1700DPI, layer thickness: 15μm | Color | Red | White |

| Material utilization | Material ≥55% | Density@90°C(Liquid) | 0.79 | 0.85g |

| Printing Speed | ≥5.5mm/h ,15μm layer | Melting Point | 68℃ | 55℃ |

| Slicing Software | WaxJetPrint | Softening Point | 63℃ | - |

| Supported File Format | stl, slc | Volumetric Shrinkage | 1.1% | - |

| Connectivity | Network 10/100/1000 Ethernet/USB/WI-FI | Linear Shrinkage | 0.7% | - |

| Supported Operating Systems | Windows 7 / Windows 10(64bit) | Needle Penetration Hardness | 9 | - |

| Working Environment | Temp 18-26℃, Humidity 30-70% | Ash Content | <0.01% | - |

| Equipment Dimensions | 1352*775*1600mm | Description | High-precision castable wax | Hands-free dissolvable support wax |

| Net Weight | 480kg | |||

| Package Size | 1530*900*1837mm | |||

| Gross Weight | 630kg |

*Conditions: ①Volumetric Shrinkage SH/T 0588-1994; ②Needle Penetration Hardness GB/T 4985-2010; ③Ash Content GB/T 14235.3-1993

Bloglar

WJ-530’u benzerlerinden ayıran en kritik özellik nedir?

WJ-530, eşzamanlı üç yazıcı kafası ile çalışır; endüstriyel kuyum üretimi için ayda ≈12 kg’a kadar model mum çıkışı ve 6.35 mm/s tepe hız sunar. Ayrıca 2900×2900×1700 DPI çözünürlük ve 15 µm katman ile yüksek hassasiyeti korur.

Baskı hacmi ve çözünürlük değerleri nedir?

Cihazın yapı hacmi 289 × 208 × 150 mm’dir. Çözünürlük 2900 × 2900 × 1700 DPI, katman kalınlığı 15 µm’dir; tipik katman süresi ≈8.2 sn’dir. Bu kombinasyon, parça yüzeyini pürüzsüzleştirip son işlem süresini azaltmaya yardımcı olur.

Hangi mum malzemeleri kullanır? Döküm ve kaplama için uygun mu?

WJ-530, kırmızı model mumu (FFWJ1200) ve beyaz destek mumu (FFWS3200) ile çalışır; %100 mum bileşimi ve kül içeriği <0.01% değeri, temiz yanma profiline ve döküm uyumuna destek olur. Üstelik kırmızı mumla üretilen kalıplar elektro kaplamaya kolay yapışır.

Uzaktan izleme ve operasyon verimliliği nasıldır?

Makinede Wi-Fi bağlantısı ve 2K HD kamera bulunur; baskılar gerçek zamanlı izlenebilir. Ayrıca malzeme kullanım oranı %58–60 aralığındadır; bu da atığı azaltıp toplam üretim verimini artırır.

Teklif Alın

Daha fazla bilgiye mi ihtiyacınız var?

Ücretsiz numune baskı alma şansı için lütfen sorgulama bilgilerinizi bırakın, 24 saat içinde yanıt vereceğiz.